(PEB) PRE-ENGINEERED STEEL BUILDINGS SERVICES IN LAHORE

ACCO (PEB) Pre Engineered Steel Buildings Services in Lahore

ACCO is a leading provider of pre-engineered steel buildings (PEB) services in Lahore, Pakistan. With over 20 years of experience, ACCO has a proven track record of delivering high-quality PEB buildings that meet the specific needs of our clients.

ACCO’s PEB buildings are made from high-quality steel that is engineered and manufactured to the highest standards. Our buildings are also designed to be energy-efficient and durable, making them a wise investment for your business or organization.

ACCO offers a wide range of PEB building services, including:

- Design and engineering

- Manufacturing

- Supply

- Erection

- Maintenance

We also offer a variety of customization options to ensure that your PEB building meets your specific needs.

If you are looking for a high-quality, affordable, and durable PEB building, then ACCO is the right choice for you. Contact us today to learn more about our PEB building services in Lahore.

Here are some of the benefits of choosing ACCO for your PEB building needs:

- We have over 20 years of experience in the PEB building industry.

- We use high-quality steel that is engineered and manufactured to the highest standards.

- Our buildings are designed to be energy-efficient and durable.

- We offer a wide range of customization options to meet your specific needs.

- We offer competitive pricing and financing options.

Contact us today to learn more about our PEB building services in Lahore.

ACCO (PEB) Pre Engineered Steel Buildings Services in Lahore

In recent years, the construction industry has witnessed a paradigm shift towards pre-engineered steel buildings (PEBs). This revolutionary technology has transformed the way buildings are designed and erected. PEBs are custom-designed steel structures that are fabricated off-site and assembled on-site. ACCO is one of the leading companies in Lahore that provides PEB services. In this article, we will explore ACCO’s PEB services in Lahore.

Introduction

- What are PEBs?

- What are the benefits of PEBs?

- Why choose ACCO for PEB services in Lahore?

ACCO’s PEB Services

- Design and Engineering

- Fabrication

- Erection and Installation

- Roofing and Cladding

- Insulation

- Ventilation

- Electrical and Plumbing

Benefits of ACCO’s PEB Services

- Customization

- Cost-effectiveness

- Time-saving

- Durability

- Energy-efficient

Applications of PEBs

- Industrial Buildings

- Commercial Buildings

- Warehouses

- Sports Facilities

- Aircraft Hangars

- Agricultural Buildings

ACCO’s PEB Projects in Lahore

- Industrial Building for Textile Industry

- Warehouse for Logistics Company

- Sports Facility for Cricket Stadium

- Aircraft Hangar for Aviation Company

- Commercial Building for Retail Outlet

Quality Control and Safety Measures

- ISO Certification

- Quality Assurance

- Health and Safety Standards

Maintenance and After-Sales Services

- Preventive Maintenance

- Repair and Replacement

- Warranty and Guarantee

FAQs

- What is the average cost of a PEB in Lahore?

- Can PEBs be used for residential purposes?

- How long does it take to erect a PEB?

- Are PEBs environmentally friendly?

- What is the lifespan of a PEB?

Conclusion

ACCO’s PEB services in Lahore provide a cost-effective, time-saving, and durable solution for industrial, commercial, and residential buildings. With a focus on quality control and safety measures, ACCO ensures that their PEB projects are of the highest standards. Their after-sales services, including maintenance, repair, and replacement, provide peace of mind to customers.

ACCO (PEB) PRE ENGINEERED STEEL BUILDINGS SERVICES IN LAHORE

Welcome to our article on ACCO (PEB) Pre Engineered Steel Buildings services in Lahore. As a leading provider of PEB services in Lahore, we understand the importance of high-quality steel buildings for both commercial and industrial purposes. In this article, we will explore what makes ACCO (PEB) Pre Engineered Steel Buildings services stand out, and how we can help you to make the most of your investment in steel buildings.

What are Pre Engineered Steel Buildings?

Pre Engineered Steel Buildings, or PEBs, are structures that are built using pre-fabricated steel components. These structures are designed to be both durable and cost-effective, and can be used for a wide range of purposes, including warehouses, factories, offices, and even homes. PEBs are becoming increasingly popular in Lahore, due to their many advantages over traditional construction methods.

Why Choose ACCO (PEB) Pre Engineered Steel Buildings?

At ACCO (PEB) Pre Engineered Steel Buildings, we are committed to providing our clients with the highest quality PEB services in Lahore. Here are just a few of the reasons why you should choose us for your next steel building project:

- Experience: With years of experience in the PEB industry, we have the expertise and knowledge needed to deliver outstanding results for our clients.

- Customization: We understand that every client has unique needs and requirements when it comes to their steel buildings. That’s why we offer a wide range of customization options to ensure that each building we construct is tailored to the specific needs of our clients.

- Quality: We use only the highest quality materials and components in our PEB constructions, ensuring that your building is built to last.

- Affordability: We believe that high-quality steel buildings should be accessible to everyone, which is why we offer our services at an affordable price point.

Our Services

At ACCO (PEB) Pre Engineered Steel Buildings, we offer a comprehensive range of services to ensure that our clients get the most out of their investment in steel buildings. Here are just a few of the services we offer:

- Design and Engineering: Our team of experienced designers and engineers will work closely with you to develop a custom design for your steel building that meets your specific needs and requirements.

- Fabrication: We use only the highest quality materials and components to fabricate the pre-engineered steel components for your building.

- Construction: Our skilled construction team will ensure that your building is constructed to the highest standards of quality and durability.

- Maintenance and Repair: We offer a range of maintenance and repair services to ensure that your steel building continues to perform at its best for years to come.

Conclusion

At ACCO (PEB) Pre Engineered Steel Buildings, we are committed to providing our clients with the highest quality PEB services in Lahore. With our years of experience, commitment to customization, use of high-quality materials, and affordable pricing, we are confident that we can help you to make the most of your investment in steel buildings. If you are interested in learning more about our services, or if you have any questions about PEBs in general, please don’t hesitate to get in touch with us today.

ACCO (PEB) Pre-Engineered Steel Buildings are high-quality steel structures that are custom designed and fabricated to meet the specific needs of clients in Lahore, Pakistan. ACCO is a leading provider of PEB services in Lahore, with a proven track record of delivering exceptional quality and customer satisfaction.

ACCO’s PEB structures are made of pre-fabricated steel components that are engineered and manufactured in a factory, which ensures high precision and accuracy in the manufacturing process. This results in a structure that is strong, durable, and able to withstand harsh weather conditions, seismic events, and other environmental factors.

ACCO’s team of engineers, architects, and project managers work closely with clients to understand their specific requirements and develop customized designs that meet their needs. They provide end-to-end solutions, from design and engineering to fabrication, transportation, and installation.

ACCO’s PEB structures are not only quick to assemble but also require minimal maintenance, which makes them a cost-effective and reliable solution for clients in Lahore. The steel used in PEB structures is 100% recyclable, which makes them an environmentally friendly choice.

ACCO’s PEB services include a wide range of applications, such as industrial buildings, commercial buildings, warehouses, airplane hangars, and more. They also offer a variety of roofing and cladding options, including insulated panels, standing seam panels, and single skin sheets.

ACCO Pre-Engineered Steel Buildings (PEB) are a leading solution for construction projects in Pakistan. PEB structures are designed and manufactured using pre-fabricated steel components that are engineered to fit specific project requirements. ACCO is a reputable PEB provider in Pakistan, offering complete end-to-end solutions from design, engineering, fabrication, transportation, and installation.

ACCO’s PEB structures are engineered to be strong, durable, and able to withstand harsh weather conditions, seismic events, and other environmental factors. PEB structures are also quick to assemble and require minimal maintenance, which makes them an ideal solution for construction projects in Pakistan.

ACCO’s team of engineers, architects, and project managers work closely with clients to understand their specific needs and develop customized designs that meet their requirements. The team ensures that every PEB structure is manufactured to the highest quality standards, using the latest technology and manufacturing processes.

ACCO’s PEB structures have a wide range of applications, including industrial buildings, commercial buildings, warehouses, airplane hangars, and more. The steel used in PEB structures is 100% recyclable, which makes them an environmentally friendly choice. In addition, PEB structures are designed to be energy-efficient, reducing the overall energy consumption of the building.

ACCO’s PEB services in Pakistan also offer a variety of roofing and cladding options, including insulated panels, standing seam panels, and single skin sheets. These options provide clients with the ability to customize their PEB structure to meet their specific requirements, including aesthetics and insulation properties.

Overall, ACCO’s PEB services in Pakistan offer a reliable, cost-effective, and customizable solution for construction projects. With a proven track record of delivering exceptional quality and customer satisfaction, ACCO’s PEB structures are a preferred choice for clients in Pakistan.

Overall, ACCO’s PEB services in Lahore offer a superior and cost-effective solution for clients who are looking for high-quality, durable, and custom-designed steel structures.

Pre Engineered Steel Buildings Services (PEB) are steel structures built over a structural concept of primary members, secondary members, roof and wall sheeting connected and various other building components. These buildings can be provided with various structural and non-structural additions such as skylights, wall lights, turbo vents, ridge ventilators, louvers, roof monitors, doors & windows, trusses, mezzanine floors, fascias, canopies, crane systems, insulation, etc., based on the customer’s requirements. All steel buildings are custom designed to be lighter in weight and high in strength. Thus steel building designs have become more flexible, durable, and adaptable over the last four decades which has made steel one of the preferred materials for building construction.

PEBs are ideal for non-residential and wide-span low-rise buildings. Some of the key advantages of PEB include economical cost, factory-controlled quality, durability, longevity, flexibility in expansion, environmentally friendly, faster installation, etc. Pre-engineered steel buildings are used for diverse applications such as factories, warehouses, showrooms, supermarkets, aircraft hangars, metro stations, offices, shopping malls, schools, hospitals, community buildings, and many more.

As a leading PEB manufacturer, ACCO provides the complete service of engineering, fabrication, and erection thus ensuring better quality control at every stage of the process.

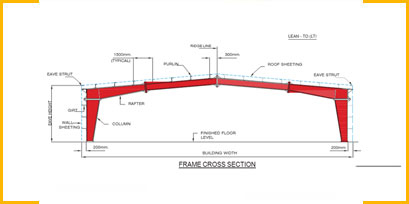

MAINFRAMES GIRDERS

Primary members are the main load-carrying and support members of a pre-engineered building. The main frame members include columns, rafters, and other supporting members. The shape and size of these members vary based on the application and requirements. The frame is erected by bolting the end plates of connecting sections together. All the steel sections and welded plate members are designed following the applicable sections as per the latest international codes and standards such as AISC, AISI, MBMA and IS to meet all the customer specifications.

TYPICAL AFTER TYPICAL COLUMN

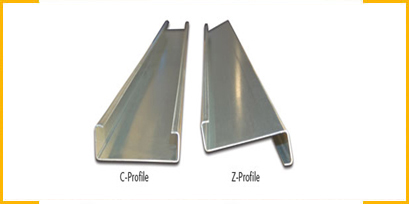

ROOF PURLINS AND WALL GIRTS

Secondary structural framing refers to purlins, girts, eave struts, wind bracing, flange bracing, base angles, clips, and other miscellaneous structural parts. Purlins, girts, and eave struts are cold-formed steel

SHEETING PROFILES

ACCO’s standard steel panels are 0.5 mm or 0.6 and mm thick and have minimum yield strength of 345 MPa. Steel panels are hot-dipped and galvanized with zinc or zinc-aluminum coating. Galvanized materials conform to G90 for 275 grams per square meter according to ASTM A653. Zinc-Aluminum-coated materials conform to AZ150 according to ASTM A792.

members which have minimum yield strength of 345 MPa (50,000 psi) and will conform to the physical specifications of ASTM 572 (Grade 50) or ASTM A653 (Grade 50) or equivalent. (ACCO) panels are prepared with a multilayered coating system to ensure long life and optimum coating adherence. The base material is pretreated, before applying a corrosion-resistant primer and topcoat. The combined thickness of the painted film is 30-35 microns on the front side and 15-17 microns on the reverse side

ACCO’s STANDARD S-PROFILE

ACCO’s Roof and Wall profile is strong and cost-effective and was developed specifically for roofing applications. The bearing leg design permits easier installation and maintenance, supports thicker layers of insulation, and allows easier curvature for a visually appealing finish.

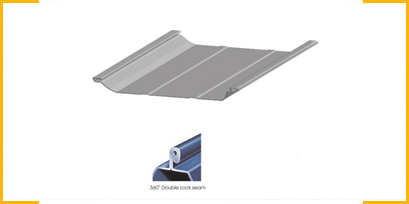

ACCO’s SEAM LOCK ROOF SYSTEMS

Standing Seam is a premium metal roofing product. This high-quality metal roof system is designed to hide the fasteners, creating a beautiful roof with the durability of steel. This panel is factory cut to half an inch. Many of our colors are Energy Star rated for great energy efficiency. Made of high tensile steel, then coated with multiple quality coatings Vertical Seam metal roofing can take it.

Whether its high winds in Faisalabad, Lahore, Quetta, Karachi Port Qasim, and the northern Area, Vertical Seam doesn’t back down to the challenge these panels help eliminate cracking and/or blistering which is common in other roof materials. It also allows roof movement for expansion and contraction along with panel strength and durability

These panels have a vertical standing seam design and are highly flexible with concealed fasteners. They provide weather-tight field seaming with no end closures. These panels enhance appearance in addition to the exceptional durability and corrosion resistance. This system is architecturally compatible with various applications

ACCO Z-SEAM STANDING SEAM

The Z-Seam ® roof panel is ideal for industrial, Commercial, and architectural applications. When Used in a Retrofit application, Double-Lok® increases the Energy efficiency and longevity of the structure.

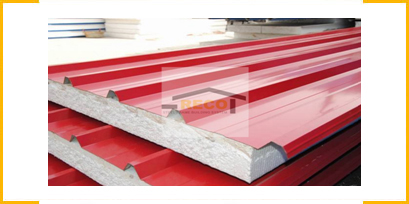

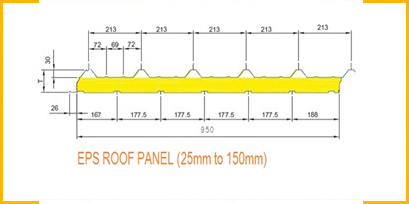

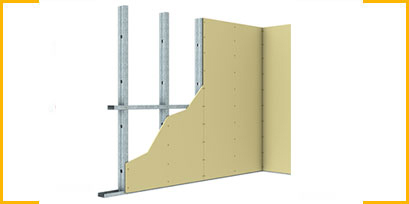

INSULATED SANDWICH PANEL

ACCO offers insulated panels with an excellent slip joint Connection for structural strength and weather tightness. The profiles shown below can be used as an inner skin For roof and wall panels and as partition panels. The inner profiles are available in four different types: Micro ribbed StrippedMicrowaveFlat ACCO’s polyurethane (PUR) and polyisocyanurate (PIR) foam and EPS Expanded polystyrene, Sandwiched by metal flexible facings is increasingly successful in

Meeting the requirements of the construction industry, with an emphasis On cost-effective building systems and conservation. Some Popular applications include industrial and Commercial Buildings, as well as the food supply sector (Cold storage, refrigerated transport, etc.). ACCO produces sandwich panels in 6 Thickness 35mm, 50 mm, 75 mm, 100 mm, 125 mm, and 150 mm. While the top and bottom profiles can be manufactured from variable selections such as the M45-250, M45-150, Microwave, Micro Ribbed, Stripped, and Flat.

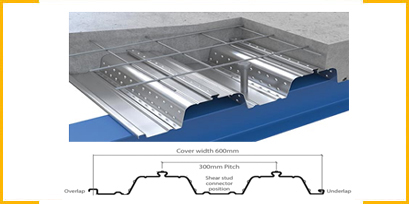

MEZZANINE SYSTEMS

• Deck sheet and • Comfloor60 ® ACCO’s Deck sheet/Comfloor are used in high-rise buildings, Office buildings, and mezzanine floors in industrial buildings and warehouses. These decks can be used As permanent shuttering to support the wet concrete And help in creating composite slabs and floor Beams. The continuous flange stiffeners and deep Embossments increase the load-carrying capacities. They provide a stable and rigid working platform Without any need for propping. These panels are roll Formed from hot-dip galvanized coils of 345 MPa With thicknesses starting from 0.6 mm to 1.2 mm.

Allowable un-supported Span: up to 4m with 125mm Concrete fill Allowable Loads for 4m clear Span: 80 psf Thickness: 0.9mm to 1.2mm Galvanized Sheets Max Load Capacity: 250 psf Standard mezzanine system consists of Comfloor 60, mezzanine joists, built-up beams, and intermediate support columns. Built-up beams span in lateral Directions and mezzanine joists in longitudinal Directions are bolted to the top flange of beams. A Concrete slab is cast on the steel deck or Comfloor As a finished surface. Steel checkered plates can also be used as top surface as per requirement

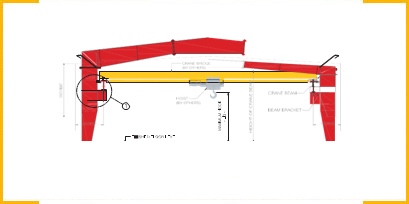

CRANE SYSTEM:

Two out of every five metal building systems are constructed for manufacturing facilities where cranes are needed for material handling RECO buildings can be designed to support any required crane system. Overhead traveling cranes, up to 15, 20, or May variable capacity metric tons are supported on brackets, while higher capacities are typically supported by an independent support system. A building crane is a complex Structural system that consists of the crane with the trolley and hoist, crane rails with their fastenings, Crane runway beams, structural Supports, stops, and bumpers. We require the customer’s complete Crane system information to Design and estimate buildings with Cranes. The estimate for adding a Crane system to a metal building Consists of: Strengthening the building mainframes to support the crane load Supplying the crane brackets and crane runway beams that support the crane system

ACCESSORIES

In addition to the main building components, ACCO provides a wide range of building accessories.

High Strength bolts:

are hot dip galvanized and conform To ASTM A325M Type 1 or equivalent. These bolts are used to connect Primary and secondary members.

Anchor Bolts:

are manufactured from rods conforming to ASTM F1554 Grade 36 or equivalent, with a minimum yield strength of 250 N/mm2 and an ultimate tensile strength of 400 N/mm2.

Fasteners

Roof and wall fasteners:(used to attach panels to purlins, Girts, etc.) Are self-drilling fasteners with a thread diameter of 5.5mm? The head is hexagonal (8mm), preassembled to a 19mm diameter washer That is bonded to a 3mm thick EPDM seal.

Stitch Fasteners:

(used at panel side laps and to attach flashings To panels) are self-drilling with a diameter of 4.8mm. The head is hexagonal And preassembled to a 16mm washer that is bonded to a 3mm thick EPDM seal. For Aluzinc-coated steel panels, the fasteners are manufactured from high-grade Carbon steel with the surface protected by a zinc-based coating of 8 microns. For aluminum panels, the fasteners head and stud are manufactured from stainless Steel, whereas the drill bit is made of hardened carbon steel. Pop rivets: are 4.0mm in diameter and made from Stainless Steel. They Are used in gutter splicing, fixing trim to trim or trim to the panel, and fastening Accessories to roof or wall panels.

Foam closures:

match the panel profile and made from expanded polyurethane or similar material. Bead Mastic: is a butyl rubber-based sealant and is Supplied in rolls on silicon release paper.

Flow-Able Mastic(Caulking Sealant):

is a Neutral silicone sealant that is chemically inert and non-corrosive. It is UV resistant and suitable for exterior applications against Weathering and rainwater. When cured it is non-toxic and will Accommodate high thermal and shrinkage changes in structural Movement joints.

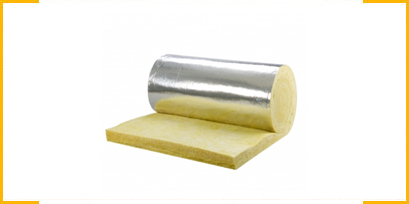

Insulation:

Fiberglass blanket composed of stable and uniformly textured inorganic glass fiber bonded together by a non-water soluble and fire retardant thermosetting resin. The standard insulation thickness is 50mm, higher thicknesses (75mm and 100mm) are available upon request.

The standard insulation facing is either Foil Reinforced Kraft (FRK) or White Metallized Scrim Kraft (WMSK). The insulation is supplied in rolls where the insulation width is 1.0 meters for WMSK facing, and 1.1 meters for FRK facing. Both types of

facings extend 50mm on each side of the insulation. The standard nominal density of the insulation is 12 kg/m3. Higher densities (16 kg/m3 and 24 kg/m3) are available upon request

Heavy Duty Personnel Doors:

Personnel doors are flush-finished and 49mm thick. Single-leaf doors are 915mm wide x 2135mm high. Double leaf doors are 1830mm wide x 2135mm high. Doors are reinforced, stiffened and sound deadened within an expanded polystyrene core, laminated to the inside faces of door panels, filling the inside cavity of the door leaf. Steel door panels are 1.2mm thick hot-dip galvanized cold rolled steel, thoroughly cleaned and painted with RAL 7035 (light gray) color finish to ensure adequate corrosion protection. Doors are factory prepared

for a cylindrical lockset. Door frames are 1.5mm thick hot-dip galvanized or equivalent, thoroughly cleaned, and painted with RAL 7035 (light gray) color finish coat. Door frames are delivered knocked down, mitered corners have brackets with pre-drilled holes for field assembly, and are supplied with all fasteners necessary for assembly. The lockset is a keyed cylindrical type with a satin chrome finish(optional panic devices and auto closers are available). Each door leaf has 3 ball bearing hinges with a security set screw in the barrel to prevent the removal of the hinge pin with the door in a closed position.

Steel Sliding Doors:

The frames of horizontal steel sliding doors are manufactured from 2mm thick cold-formed channels and girts and are delivered knocked down for field assembly. All clips, fasteners, and other items necessary for assembly are provided. The exterior face of the door leaf is sheeted with profiled panels that match the profile and material of the wall panel.

Door leaves are suspended from an exterior mounted trolley rail, attached to a structural header beam.

The door hood trim, to conceal and protect the header and rail, is supplied in the same material as the wall panel. Doors are bottom guided by a specially designed steel rail track. Sliding doors may also be provided with flush-hinged pilot doors. A pilot door is a personnel door located within a leaf or a sliding door.

Adjust Able Steel Louvres:

Adjustable steel louvers are 0.9 meters wide x 1 meter high. They are supplied complete with a galvanized steel mesh, blades, and framing. Made from 0.5mm pre-painted Aluzinc coated steel sheet and are only available in off-white color.

Gravity Ventilators:

Gravity ridge ventilators are 3 meters long, with a throat opening of 600mm, and without a damper. They are installed as either individual units or as continuous (ex: joined) units. The outer skin of the ventilators is made from the same material as the profiled roof panels. The ventilators are supplied complete with bird screens. Ventilators are shipped knocked down and ready to be assembled on site

Fiberglass Roof Skylights:

Translucent reinforced Corrugated fiberglass skylight panels substantially reduce the amount Of artificial illumination and electricity needed to light the inside of your building. Various corrugated shapes are available to nest with existing corrugated metal Panels eliminating the need for additional flashing or roof curbs. Skylights can also be fabricated onto a built-up roof curb for flat roofs or Membrane roof areas where light is required.

Steel Roll-up Doors:

A roll-up door curtain is cold-formed from hot-dip galvanized steel and painted with polyester paint in off-white color. The bottom rail of the door curtain is an extended aluminum angle guide. The door drum, supporting the door curtain, houses safety springs, end shafts, Collars, and bearings. Doors are supplied complete with guides, axle, curtain, manual chain, and a reduction gear operating system. Electrically operated doors are available as an option, upon request.

Windows:

Window frames are made of anodized or powder-coated aluminum extrusions and are horizontal, half slide type, 1 meter high, and 1 meter wide, specifically designed for installation in profiled exterior wall panels. Windows are factory glazed with 6mm thick clear glass and are equipped with latches and removable insect screens.

Light Gauge Steel Buildings in Pakistan

Five Sections Do It All

Different sizes and gauges of this five-section can virtually design and build any size or configuration of building, from small to large or single to multi-storied.

Truss Framing

Light Gauge Metal Trusses are characterized by their triangular and are most often used in roof construction.

Wall Framing

Light-Gauge Metal Wall Frames are made with “C” and “U” with cross bracing strips at wall frame corners.

Wall / Roof Cladding Boards

Various kinds of building boards/cladding sheets are used to clad the steel structures as per client requirements, such as Fiber Cement Board. Cement particleboard. Magnesium oxide fire roof board. Gypsum fiberboard. Trapezoidal Sheeting. Fiber cement board is an environmentally friendly, innovative lightweight cellulose fiber reinforced cement product that provides high-quality full-range application for ceiling, siding, and flooring incomplete system solutions.

Modular Sandwich Panel in Lahore Pakistan

MODULAR SANDWICH PANELS

(ACCO) The modular Sandwich panel comprises two metal faces and a fully insulating core. The insulating core is typically bonded to the facings using a conventional adhesive bond. The metal facings are fully bonded to the core so that the panel acts compositely when under load, in most cases, providing free-standing panels. The facings used for insulated panels are predominantly of steel.

General Steel Structure in Pakistan

(ACCO) Steel Buildings provides a line of structural steel building systems that are of unmatched quality and design. Through innovative technology, as well as the latest advances in machinery, (ACCO) can handle any size project. Whether you are seeking a single-story structure, or a multi-level steel building, (ACCO) Steel Building gives you economical pricing and exacting manufacturing time. Trust your structural steel building needs to Reco, the leader in pre-engineered steel and metal building solutions worldwide.

We have lots of engineers in-house providing the best-integrated design, BIM, engineering, and detailing. Our Factory 150,000 square foot structural steel shop located near the Raiwind Manga Road and metal building component manufacturing facilities features:

Our professional staff of engineers can assist with any technical inquiries. All welding and welders are qualified in compliance with AWS D1.1 and D1.3 codes of construction.

We also have an AWS Certified Welding Inspector (CWI) on staff. Combined Rigid has 75,000 square feet of fabrication and manufacturing space.

- Several Heavy Duty Cranes

- Plasma Cutters

- Fitting and Welding Stations

- Plate Maker

- Automated Welding Line

- Shot Blasting

- Straightener

We offer Cement Industries, Bridges, and Power Plant, our project highlights include:

- Warehouse

- Manufacturing

- Municipal

- Educational

- Religious

- Medical

- Office

- Retail

The market share demand for structural steel is significantly higher than for pre-engineered buildings which is the primary reason Rigid moved forward with the development of the new structural shop. Non-residential construction, multi-story residential construction including hotels and dormitories, and non-building structures including open-air stadiums, chemical plants, power plants, refiners, and other buildings that do not have a roof are all structural segments that are anticipating growth over the next 5 years.

(ACCO) Modular Sandwich panels are made on the continuous production line with EPS-insulated materials that have multiple applications. These modular panels are manufactured in a variety of attractive colors, thicknesses, and sheet materials.

PE film is pasted on these panels on these panels to ensure the safekeeping of panels at sites.

(ACCO) Modular Sandwich panels have a tongue & grove joining system and are conveniently assembled ad dissembled at sites without any wastage. The panels are so very lightweight that they can be transported to every kind of difficult location.

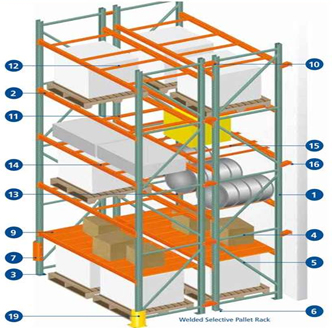

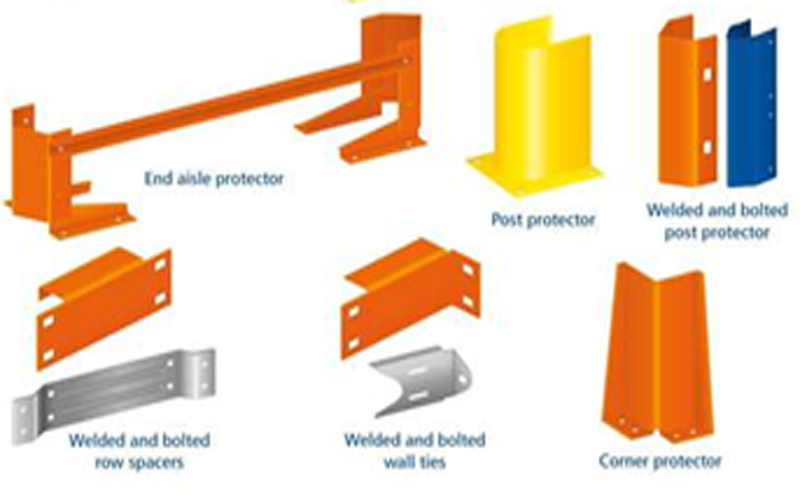

Racking System in Lahore Pakistan

Components:

- Frame

- Beam

- Horizontal Strut

- Diagonal Strut

- Shim

- Post Protector

- End Aisle Protector

- Shelf Panel

- Row Spacer

- Roll-in Pallet Support

- Double Flanged Pallet Support

- Drum/Coil Bed

- Fork Clearance Bar

- Skid Channel

- Wall Tie

- Drum Cradle

- Corner Protector

- Post Protector

A variety of accessories are available for selective Rack systems. From pallet supports to column protectors, interlake Mecalux has accessories to meet any need. For a complete list of accessories, please contact your interlake Mecalux representative.

OUR PRODUCTS

- Pallet Racks

- Shelf Racks (Fixed Pallet, Mesh Pallet)

- Cantilever Racks

- Light Duty Racks

- Heavy Duty Racks

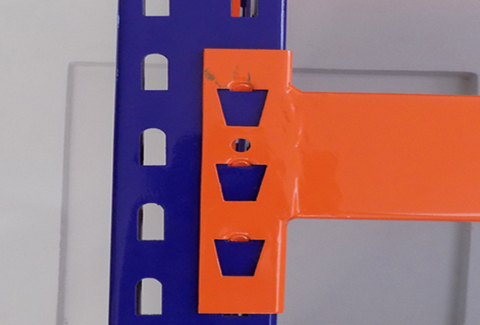

Pallet Racking System

ACCO’s Pallet Racking in Pakistan specializes in the design, manufacture, and installation of a wide range of versatile storage equipment from adjustable beam pallet racking in Pakistan and heavy-duty shelving, to ‘live storage and fully integrated ‘turnkey’ warehouse schemes. We operate production techniques that are the most efficient in the industry.

Beams can be removed and repositioned when changes in the use of the racking are adjustable, once the beams are slotted into position in the frame uprights, an interlocking structure of great strength and rigidity is maintained. We have been providing pallet racking in Pakistan for more than two decades to various industries. Our racking solutions in Pakistan are most preferred among different sectors. From selective pallet racking solutions to drive-through racking solutions in Pakistan, we have got you covered Heavy Duty Racks/Shelving unit is mainly constructed and designed for tough loads between 1000kg – 3000 kgs/UDL (Uniformly Distributive Load) where it is the most suitable system for heavy-capacity warehouse users. Heavy-duty industrial shelf racks are used in various places like Offices, Police stations, Warehouses, Grocery shops, Stalls, the Metal industry, the Chemical industry, etc. The box beam as the levels increased the loading capacity of the Heavy Duty Industrial Shelving Racks. The flexibility of the box beam bracket enables an easier installation process

Features of Heavy-Duty Racks

Customized sizes are also available for specific storage needs. A DURABLE Antirust frame ensures long use life.STURDY Solid structure with high capacity. Strength and also rigidity prevents compression damage to goods. Maximize space use in any warehouse configuration while retaining optimum product accessibility. High-quality steel High-quality Powder Coating Finish.

The racks built from robust metal, ensure suitability for heavy duty.

Shelf Racking System

Space is a big problem facing many people. Proper usage of space and the need for maximizing available floor space have become very essential. The shelf rack is a flat horizontal plane which use in the home, business, store, or elsewhere to hold items that are displayed, stored, or exist for sale.

These shelving units raised off the ground are usually supported on shorter-length sides by brackets Shelf racks known as counters, mantels, and similar to individual shelving units. A shelf rack can attach to a wall or another vertical surface, and be put in a corner or storage on the floor. It can be part of a piece of furniture such as a cabinet, bookcase, and so on. Usually, two to six shelves make a unit, each shelf attached up and down to vertical or sloping chains and positioned parallel above the other. The size of shelving units is based upon the space boundary of sitting and the amount of load which will be expected to hold.

Shelves are made of strong materials like wood, steel, or iron. Shelf racks hold lighter-weight objects made of plastic, glass, or wood. It consists of a wood board resting on black and energizes steel or metals. The length and size of the shelf to the wall differ depending on the material of the wall. Shelf racks make suitable for all kinds of companies.

Advantages of Shelf Rack

A shelf-racking system saves you a lot of valuable floor space. Shelf racks are quite durable. They are versatile and also rust-free. Available in different sizes. They help to organize and store things efficiently.

Up to 60% less space than conventional racking Automatic stock rotationFIFO load and retrieval method only requires two aisles High-speed operation.

Features of Shelf Rack

Heavy-duty construction for strength and rigidityDurableWeight capacity up to 4000 lbs distributed evenly over the entire unit5 particle

board shelves adjust every 1.5″ and have a durable black finish

-

Pre-Engineered Steel Buildings (P.E.B)

-

Light Gauge Steel Frame Buildings (LGSF)

-

Sandwich Panel Buildings (EPS & PU)

-

Mechanical Fabrication of Mild Steel

-

Mechanical Fabrication of Stainless Steel

ACCO Engineering Services was formed to deliver quality products precisely meeting the specifications and requirements of the clients within the given time at quite competitive prices.

Holds 800 lbs per shelf or 4000 lbs total

Projects

We’ve Done Lot’s Projects Let’s Check Some Here

Air Craft Hanger

Warehouse/Industrial Shed

Multi-Purpose Hall

Dairy/Parking Shed

Workshop Shed

Crane Shed

Modular Sandwich Panel

General Str / Multi-Story

ACCO (PEB) Pre Engineered Steel Buildings Services in Lahore: A Complete Guide

If you’re in the market for a durable, versatile, and cost-effective building solution, pre-engineered steel buildings may be just what you’re looking for. And if you’re in Lahore, Pakistan, ACCO is one of the top companies providing PEB (pre-engineered building) services. In this article, we’ll cover everything you need to know about ACCO’s PEB services in Lahore, including what PEB is, the benefits of using PEB, and the specific services offered by ACCO.

Table of Contents

- What is PEB?

- Benefits of PEB

- ACCO’s PEB Services

- Design and Engineering

- Fabrication

- Erection

- Maintenance and Repair

- PEB vs. Traditional Construction

- PEB Applications

- Why Choose ACCO?

- FAQ

- Conclusion

- Access More Amazing Prompts

What is PEB?

PEB stands for pre-engineered building, which is a type of building system that is designed and manufactured off-site, then transported to the construction site for assembly. PEB buildings are typically made of steel, although other materials may be used for certain components. The design and engineering of PEB buildings are done using specialized software that takes into account the specific needs and requirements of the building.

Benefits of PEB

There are many benefits to using PEB buildings, including:

- Cost-effectiveness: PEB buildings are often less expensive than traditional construction methods due to the efficiency of the manufacturing process and the use of standardized components.

- Quick construction: Because much of the building is pre-fabricated, PEB buildings can be assembled much more quickly than traditional construction.

- Durability: Steel is an incredibly durable material that can withstand extreme weather conditions, fire, and other hazards.

- Versatility: PEB buildings can be designed to fit a wide range of applications, from simple storage sheds to complex commercial and industrial buildings.

ACCO’s PEB Services

ACCO is a Lahore-based company that provides a full range of PEB services, including:

Design and Engineering

ACCO’s team of experienced engineers and designers use state-of-the-art software to create customized PEB building designs that meet the unique needs of each client. They take into account factors such as site conditions, intended use, and local building codes to ensure that the design is both functional and safe.

Fabrication

ACCO’s fabrication facility is equipped with the latest technology and equipment, allowing them to produce high-quality PEB components quickly and efficiently. They use only the best materials and follow strict quality control procedures to ensure that each component meets or exceeds industry standards.

Erection

ACCO’s skilled team of erection specialists has years of experience in assembling PEB buildings quickly and safely. They follow strict safety procedures and use specialized equipment to ensure that the building is erected correctly the first time.

Maintenance and Repair

ACCO also provides ongoing maintenance and repair services for PEB buildings. Their team of technicians can perform regular inspections and maintenance tasks to ensure that the building remains in top condition. In the event of damage or other issues, they can quickly repair or replace damaged components to minimize downtime and ensure that the building is safe and functional.

PEB vs. Traditional Construction

PEB buildings offer several advantages over traditional construction methods, including cost-effectiveness, faster construction times, and greater durability. Traditional construction methods can be more time-consuming and costly due to the need for on-site construction and the use of non-standardized components. Additionally, traditional building materials such as wood and concrete may not be as durable as steel, particularly in areas with extreme weather conditions or other hazards.

P

PEB Applications

PEB buildings are versatile and can be used for a wide range of applications, including:

- Warehouses and storage facilities

- Factories and industrial buildings

- Commercial buildings, such as offices and retail spaces

- Agricultural buildings, such as barns and storage sheds

- Sports facilities, such as gymnasiums and indoor arenas

Why Choose ACCO?

ACCO is one of the top PEB providers in Lahore, with years of experience in designing, manufacturing, and erecting high-quality PEB buildings. They use the latest technology and equipment, and their team of experts is committed to providing personalized service and attention to each client. With ACCO, you can be confident that your PEB building will be designed, manufactured, and erected to the highest standards of quality and safety.

FAQ

- What is the cost of a PEB building from ACCO?

- The cost of a PEB building from ACCO depends on several factors, including the size and complexity of the building, the intended use, and the specific components and features selected. Contact ACCO for a personalized quote based on your needs.

- How long does it take to erect a PEB building from ACCO?

- The time it takes to erect a PEB building from ACCO depends on the size and complexity of the building, as well as the specific site conditions. In general, however, PEB buildings can be assembled much more quickly than traditional construction methods.

- Can ACCO provide ongoing maintenance and repair services for my PEB building?

- Yes, ACCO provides ongoing maintenance and repair services for PEB buildings. Contact them for more information about their maintenance and repair programs.

- Can ACCO design and manufacture PEB buildings for custom applications?

- Yes, ACCO can design and manufacture PEB buildings for a wide range of custom applications. Contact them for more information about their custom design and engineering services.

- Is steel the only material used in PEB buildings?

- While steel is the most common material used in PEB buildings, other materials may be used for certain components, such as roofing or insulation. Contact ACCO for more information about the specific materials used in their PEB buildings.

Conclusion

ACCO is one of the top providers of PEB services in Lahore, with a full range of design, engineering, fabrication, erection, and maintenance services available. PEB buildings offer many advantages over traditional construction methods, including cost-effectiveness, faster construction times, and greater durability. Contact ACCO today to learn more about their PEB services and how they can help you meet your building needs.

Introduction to ACCO Prefabricated Buildings

In an era where time is as valuable as the investments we make, the construction industry has seen a revolutionary shift towards more efficient building methods. Among these innovations, prefabricated multi-storey buildings stand out for their remarkable benefits, including reduced construction times, cost efficiency, and minimal environmental impact. ACCO, a leading manufacturer in this space, has set new standards for quality and sustainability in prefabricated construction.

The Evolution of Prefabricated Buildings

Prefabricated construction isn’t a new concept, but its adoption and sophistication have skyrocketed in recent years. The drive towards more sustainable and efficient construction methods has led to significant advancements in the materials and technologies used in prefab buildings. ACCO has been at the forefront of this evolution, continually pushing the boundaries of what’s possible in prefab construction.

Why Choose ACCO for Your Multi-Storey Building?

ACCO offers a compelling proposition for anyone considering a multi-storey building project. Their approach combines cutting-edge design, engineering excellence, and a commitment to sustainability. This trifecta ensures that each project is not just a building, but a landmark of modern construction methods.

ACCO’s Design Innovations

At the heart of ACCO’s success are its design innovations. The company leverages the latest in architectural trends and technologies to create buildings that are not only functional but aesthetically pleasing. Their use of modular components allows for a level of customization and flexibility that traditional construction methods can’t match.

Environmental Sustainability

Sustainability is no longer just a buzzword but a crucial consideration in new constructions. ACCO’s buildings are designed with this in mind, utilizing materials and processes that minimize environmental impact. From energy efficiency to reduced waste, ACCO’s commitment to the environment is evident in every project.

The Process of Building with ACCO

Building a multi-storey structure with ACCO is a streamlined and efficient process that can be broken down into several key steps:

Step 1: Planning and Design

The journey begins with thorough planning and design, where clients’ visions are transformed into detailed blueprints. This stage ensures that every aspect of the building meets the client’s needs and preferences.

Step 2: Fabrication

With the designs in hand, ACCO’s state-of-the-art manufacturing facilities spring into action, creating the building’s components with precision and care. This phase benefits from strict quality control measures, ensuring every piece meets ACCO’s high standards.

Step 3: Site Preparation

While components are being fabricated, the construction site is prepared. This involves clearing the land, laying foundations, and preparing for the assembly of the prefabricated parts.

Step 4: Assembly and Finishing

The final step is where the magic happens. The prefabricated parts are transported to the site, where they are assembled into a fully functional building. The speed and efficiency of this process are unmatched in traditional construction.

Case Studies: Successful ACCO Projects

ACCO’s portfolio includes a wide range of successful projects, from residential buildings to commercial complexes. Each case study highlights the company’s ability to deliver high-quality, sustainable, and aesthetically pleasing multi-storey buildings across various sectors.

The Future of Construction with ACCO

As the construction industry continues to evolve, ACCO is well-positioned to lead the way in prefabricated building solutions. Their ongoing investment in technology and sustainability ensures that their buildings will meet the demands of the future, today.

Conclusion

ACCO Prefabricated Multi-Storey Building Manufacturer stands as a beacon of innovation, efficiency, and sustainability in the construction industry. Their commitment to excellence in every aspect of their work makes them the go-to choice for anyone looking to invest in a prefabricated multi-storey building.

FAQ

What is Prefabricated Construction?

Prefabricated construction involves manufacturing parts of a building in a factory before transporting them to the construction site for assembly. This method offers numerous benefits, including reduced construction time and environmental impact.

Why are Multi-Storey Buildings Important?

Multi-storey buildings are crucial for urban development, allowing for higher density living and working spaces in areas with limited land availability. They are essential for the sustainable development of cities.

How Long Does Construction Take?

The construction time can vary depending on the project’s size and complexity. However, prefabricated buildings typically take less time to construct than traditional buildings due to the efficiency of the manufacturing and assembly processes.

Can ACCO Buildings Be Customized?

Yes, one of the significant advantages of ACCO’s prefabricated buildings is their flexibility in design. Clients can work with ACCO’s designers to ensure their building meets their specific needs and preferences.

How Does ACCO Contribute to Sustainability?

ACCO’s commitment to sustainability is evident in its use of environmentally friendly materials, energy-efficient designs, and processes that reduce waste and carbon footprint.

PPLICATIONS OF PREFAB MULTI-STORY BUILDING IN Pakistan

A pre-engineered and prefabricated multi-storey building is a unique solution for a wide range of applications and can suit varying customer demands. A sturdy construction and ergonomic design makes these structures favorable for the following applications:

Construction sites

- Site accommodation

- Marketing structures

Emergency accommodation

- Control rooms

- Disaster management shelters

- Emergency accommodation

Educational buildings

- Classrooms

- Teaching blocks

- Workshops and laboratories

- Outdoor recreational buildings

Events

- Catering units

- First aid posts

- Offices

Healthcare

- Emergency health centers

- Voluntary clinics

- Re-locatable wards

Offices

- Prefab office building

- Small and medium scale business accommodations

Storage buildings

- Warehouses

- Godow

Outline

- Introduction to Prefab Multi-Story Buildings

- Definition and Concept

- Growing Popularity

- Applications in Construction Sites

- Temporary Offices

- On-site Accommodation

- Marketing Structures and Promotional Events

- Customizable Design

- Quick Installation

- Emergency Accommodation and Disaster Management

- Rapid Response Solutions

- Versatility in Crisis Situations

- Educational Buildings and Institutions

- Flexible Classroom Solutions

- Cost-Effective Expansion

- Outdoor Recreational Buildings

- Events and Gatherings

- Convenient Catering Units

- Healthcare Facilities

- Emergency Health Centers

- Mobile Clinics

- Prefab Office Buildings for Businesses

- Scalable Solutions for Growing Companies

- Budget-Friendly Options

- Storage Buildings for Various Purposes

- Warehouses and Godowns

- Flexible Storage Solutions

- Conclusion

Applications of Prefab Multi-Story Building in Pakistan

If you have ChatGPT 4, then try this: https://bit.ly/Jumma_GPTs

Introduction to Prefab Multi-Story Buildings

Prefab multi-story buildings have emerged as a revolutionary solution in the construction industry, offering a blend of efficiency, durability, and versatility. These structures are pre-engineered and prefabricated, allowing for rapid deployment and customization according to diverse needs. In Pakistan, where the demand for innovative building solutions is on the rise, prefab multi-story buildings are gaining traction across various sectors.

Applications in Construction Sites

Construction sites often require temporary facilities for offices, storage, and accommodation. Prefab multi-story buildings serve as an ideal solution, providing quick setup and easy relocation as projects progress. These structures offer a comfortable working environment for construction teams and facilitate seamless project management.

Marketing Structures and Promotional Events

In the realm of marketing and promotional events, the flexibility of prefab multi-story buildings shines through. With customizable designs and rapid installation capabilities, these structures become eye-catching brand showcases and event spaces. Whether it’s a product launch, trade show, or marketing campaign, prefab buildings offer a versatile platform to engage audiences effectively.

Emergency Accommodation and Disaster Management

During emergencies such as natural disasters or humanitarian crises, the need for rapid accommodation and shelter is paramount. Prefab multi-story buildings provide a swift and reliable solution, offering sturdy shelters for displaced individuals, emergency response teams, and relief efforts. Their modular design allows for quick assembly in challenging environments, ensuring timely assistance to those in need.

Educational Buildings and Institutions

Educational institutions in Pakistan often face challenges related to space constraints and infrastructure development. Prefab multi-story buildings offer a cost-effective solution for expanding campuses, adding classrooms, teaching blocks, workshops, and laboratories as needed. These structures enable educational institutions to accommodate growing student populations without compromising on quality or safety.

Outdoor Recreational Buildings

From community events to outdoor gatherings, prefab multi-story buildings offer versatile spaces for various recreational activities. Whether it’s hosting cultural events, festivals, or providing catering units for outdoor weddings, these structures provide a convenient and functional solution. Their modular design allows for easy customization to suit different event requirements.

Healthcare Facilities

In the healthcare sector, especially in underserved areas, access to medical facilities is crucial. Prefab multi-story buildings can be deployed as emergency health centers, mobile clinics, and re-locatable wards, providing essential healthcare services where they are needed most. These structures offer flexibility and scalability to meet the evolving demands of healthcare delivery.

Prefab Office Buildings for Businesses

Small and medium-scale businesses in Pakistan often face challenges related to office space and infrastructure. Prefab office buildings offer a practical solution, providing scalable accommodations that align with business growth. These structures are cost-effective, quick to install, and customizable, making them ideal for startups, remote offices, and temporary business expansions.

Storage Buildings for Various Purposes

In the realm of logistics and warehousing, prefab multi-story buildings offer flexible solutions for storage needs. Whether it’s warehouses, godowns, or distribution centers, these structures provide ample space for inventory management and logistics operations. Their modular design allows for efficient utilization of vertical space, maximizing storage capacity while minimizing footprint.

Conclusion

Prefab multi-story buildings present a myriad of applications across diverse sectors in Pakistan. From construction sites to educational institutions, healthcare facilities to recreational spaces, these structures offer a blend of functionality, efficiency, and cost-effectiveness. As the demand for innovative building solutions continues to grow, prefab multi-story buildings stand poised to redefine the landscape of construction and infrastructure development in Pakistan.

Unique FAQs

Are prefab multi-story buildings durable enough for long-term use? Prefab multi-story buildings are constructed using high-quality materials and adhere to stringent safety standards, ensuring durability and longevity.

Can prefab buildings be customized according to specific requirements? Yes, prefab multi-story buildings offer a high degree of customization, allowing for tailored designs to meet the unique needs of each project or application.

How long does it take to install a prefab multi-story building? Installation times vary depending on the size and complexity of the structure, but prefab buildings are known for their quick setup compared to traditional construction methods.

Are prefab multi-story buildings environmentally friendly? Many prefab building manufacturers prioritize sustainability in their construction processes, utilizing eco-friendly materials and efficient manufacturing techniques to minimize environmental impact.

What maintenance is required for prefab multi-story buildings? Like any structure, prefab buildings require regular maintenance to ensure optimal performance and longevity. However, their modular design often simplifies maintenance tasks compared to traditional buildings.

Prefabricated Hospital / Medical Facility Buildings Construction / Manufacturer

In the realm of healthcare infrastructure, the emergence of prefabricated technology has been revolutionary. While not entirely novel, recent studies by prominent auditing firms suggest that modular construction holds the key to the future, offering a myriad of advantages over traditional building methods.

The Rise of Modular Construction

Understanding Modular Technology

Modular construction, pioneered in 2018, represents a paradigm shift in the creation of healthcare spaces. Unlike traditional methods, modular construction involves the assembly of complete patient rooms in a controlled factory environment, tailored precisely to client specifications. These modular units are then transported to the construction site for swift installation.

Advantages Over Traditional Construction

Durability and Speed

Prefabricated modular hospitals prioritize safety, hygiene, and ergonomics while adhering to rigorous construction standards. At ACCO, for instance, our prefab hospital units encompass ICU facilities, general wards, laboratories, physician offices, and more. Constructed with global standards in mind, our facilities offer a swift assembly process coupled with cost-efficiency.

Adapting to Post-Pandemic Needs

Meeting Healthcare Demands

The flexibility of prefabricated healthcare structures has become particularly evident in the wake of the COVID-19 pandemic. These modular buildings can swiftly accommodate new hospital requirements or modifications to existing facilities. ACCO, for example, offers single-floor isolation wards, disinfection chambers, and multi-story hospital buildings, providing adaptable solutions to evolving healthcare needs.

Rapid Deployment in Emergencies

The agility of prefab construction shines during emergencies, such as pandemics. With the ability to swiftly deploy isolation wards, testing labs, and medical facilities, prefabrication technology ensures readiness in critical situations. By streamlining the construction process and eliminating weather-related delays, prefab hospitals can be erected 60-70% faster than traditional structures.

Unveiling the Key Advantages

Speed

Recent endeavors exemplify the remarkable speed of prefab construction. In Madurai, Tamil Nadu, ACCOerected a 15,000 square foot COVID hospital in just 20 days using liftable porta cabins. This rapid deployment underscores the efficiency and timeliness of modular construction.

Cost Efficiency

Prefab materials offer long-term cost savings due to their reusability and ease of dismantling. Moreover, offsite construction in a controlled environment ensures precision and quality, minimizing the risk of errors and reducing overall expenditure.

Longevity

The durability of prefab structures is a testament to their quality and precision. With rigorous quality checks and adherence to international construction standards, prefab hospitals boast longevity and resilience against wear and tear.

Conclusion

In conclusion, the advent of prefabricated technology heralds a new era in healthcare construction. With unparalleled speed, cost efficiency, and durability, prefab hospitals stand as a beacon of innovation in the face of evolving healthcare demands.

FAQs

Are prefab hospitals as durable as traditional ones? Prefabricated hospitals undergo rigorous quality checks, ensuring durability comparable to traditional structures.

How do prefab hospitals contribute to cost savings? Prefabricated materials are reusable and incur lower construction costs due to streamlined assembly processes.

Can prefab hospitals be customized to specific requirements? Yes, modular construction allows for precise customization to meet the unique needs of healthcare facilities.

Are prefab hospitals suitable for long-term use? Absolutely, prefab hospitals are built with longevity in mind, offering resilience and durability over time.

What sets prefab hospitals apart during emergencies? The rapid deployment capabilities of prefab construction make them indispensable during crises, ensuring swift response and readiness.

Introduction to Prefab Schools

- Definition and concept

- Importance in modern education infrastructure

Advantages of Prefab Schools

- Cost-effectiveness

- Time-saving construction

- Customization options

- Environmental sustainability

ACCO Prefab: Leader in Prefabricated School Buildings

- Company overview

- Reputation for quality and innovation

Range of Prefab School Buildings

- Portable school buildings

- Modular prefab colleges

- Features and specifications

Design Considerations

- Natural daylight and ventilation

- Load-bearing capacity

- Student-friendly features

Features of ACCO Prefab Schools

- Electrical requirements

- Customized construction

- Insulated panels for all weather conditions

Conclusion

FAQs

PREFAB SCHOOLS THAT ARE STURDY, COZY, AND COMFORTABLE

If you have ChatGPT 4, then try this: https://bit.ly/Jumma_GPTs

Introduction to Prefab Schools

In today’s rapidly evolving educational landscape, the demand for innovative solutions in school infrastructure is higher than ever. Prefabricated (prefab) schools have emerged as a viable alternative to traditional construction methods. These schools are constructed off-site in controlled environments, then transported and assembled on location. This approach offers numerous benefits in terms of efficiency, cost-effectiveness, and sustainability.

Advantages of Prefab Schools

Cost-effectiveness

Prefab schools typically cost less to build than traditional brick-and-mortar structures. The streamlined construction process, coupled with reduced labor and material expenses, results in significant cost savings for educational institutions.

Time-saving construction

One of the most compelling advantages of prefab schools is their shortened construction timeline. Since the components are manufactured off-site, construction can proceed simultaneously with site preparation, drastically reducing the overall project duration.

Customization options

ACCO Prefab, a leading manufacturer of prefabricated school buildings in India, offers a wide range of customization options to meet the unique needs of each educational institution. From layout design to interior finishes, schools can tailor their prefab buildings to align with their specific requirements and aesthetic preferences.

Environmental sustainability

Prefab schools are inherently more sustainable than traditional construction methods. The controlled manufacturing process minimizes waste and optimizes resource utilization, while energy-efficient features such as insulated panels contribute to reduced carbon emissions and long-term operational savings.

ACCO Prefab: Leader in Prefabricated School Buildings

ACCO Prefab stands at the forefront of the prefab construction industry, renowned for its commitment to quality, innovation, and customer satisfaction. With a diverse portfolio of projects across India, ACCO Prefab has established itself as a trusted partner for educational institutions seeking reliable and cost-effective building solutions.

Range of Prefab School Buildings

ACCO Prefab offers a comprehensive range of prefab school buildings designed to accommodate various educational needs and preferences. From portable school buildings equipped with PUF insulated panels to modular prefab colleges featuring customizable layouts and advanced amenities, ACCO Prefab delivers tailored solutions to enhance the learning environment.

Design Considerations

Natural daylight and ventilation

ACCO Prefab prioritizes the integration of natural daylight and proper ventilation in its school designs. Ample windows and skylights ensure a well-lit and airy interior, creating a conducive learning environment for students and teachers alike.

Load-bearing capacity

Every prefab school building by ACCO Prefab is engineered to withstand the rigors of educational use. Rigorous testing and quality control measures ensure superior load-bearing capacity, structural integrity, and durability, providing peace of mind to school administrators and stakeholders.

Student-friendly features

In addition to structural robustness, ACCO Prefab designs its schools with a focus on student comfort and usability. Thoughtfully planned layouts, ergonomic furniture, and amenities such as fully equipped electrical systems contribute to a positive and enriching educational experience.

Features of ACCO Prefab Schools

- Fully equipped with all electrical requirements, including wiring, sockets, and light fixtures

- Cleverly designed to withstand dead load, wind load, seismic activity, and other environmental factors

- Custom-built and pre-engineered construction with PUF insulated panels or EPS insulated panels

- Options available with various finishes, including PPGS/GI with paint on one or both sides

Conclusion

Prefab schools represent a modern, efficient, and sustainable approach to educational infrastructure development. With ACCO Prefab’s expertise and commitment to excellence, educational institutions can build sturdy, cozy, and comfortable learning environments that foster student success and well-being.

FAQs

Are prefab schools as durable as traditional brick-and-mortar buildings?

- Yes, prefab schools undergo rigorous testing and quality control measures to ensure structural integrity and durability comparable to traditional construction.

Can prefab schools be customized to fit specific design preferences?

- Absolutely, ACCO Prefab offers a wide range of customization options, allowing schools to tailor their buildings to meet their unique requirements and aesthetic preferences.

How long does it take to construct a prefab school building?

- The construction timeline for prefab schools varies depending on factors such as size, complexity, and site conditions. However, prefab construction typically takes less time than traditional methods due to the off-site manufacturing process.

Are prefab schools environmentally friendly?

- Yes, prefab schools are inherently more sustainable than traditional construction methods due to reduced waste generation, optimized resource utilization, and energy-efficient design features.

What maintenance is required for prefab school buildings?

- Prefab school buildings require regular maintenance, including routine inspections, cleaning, and occasional repairs. However, the durable materials and quality construction ensure minimal upkeep compared to traditional structures.